Types of tanks and its various categories

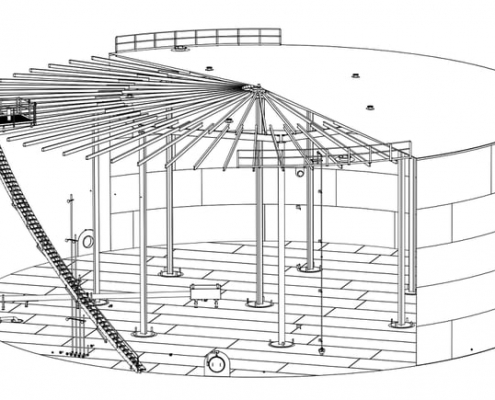

In this type of tanks, the fluid pressure is in the range of atmospheric pressure and they are used to store materials. Fixed storage tanks are a variety of air and ground tanks used to store water, fuel and industrial materials in refineries, power plants, petrochemicals and other industrial sites. Storage tanks are used in the petrochemical industry to store gaseous liquids, chemicals, water, etc. Storage tanks have a pressure below 15 PSI. In general, storage tanks are divided into the following types.

- Atmospheric pressure storage tanks with a maximum pressure of 5 PSI.

- Low pressure storage tanks designed for operation between 5 PSI and 15 PSI and their temperature up to 50 ° below zero.

Different stages of technical inspection of tanks:

Inspection during construction:

- Inspection of the manufacturer’s factory (devices and equipment necessary for construction)

- PIM session and ITP setting

- Check the submitted maps and confirm them

- Check welding instructions (WPS) and their approval (PQR)

- Control of consumable materials (sheets, pipes and other materials used in the manufacturing process)

- Supervision of assembly and dimensional control according to the approved plan

- Perform non-destructive tests (VT, PT, MT, UT, RT, Pha) if required

- Padding according to the approved plan

- De-escalation

- Hydrostatic test after stress relief

- Install all valves and tank fittings

- Testing and certification of safety valves and valves

- Preparation of inspection booklet during construction (including all available documents and inspection reports)

- Certification and inspection plate during construction according to the standard

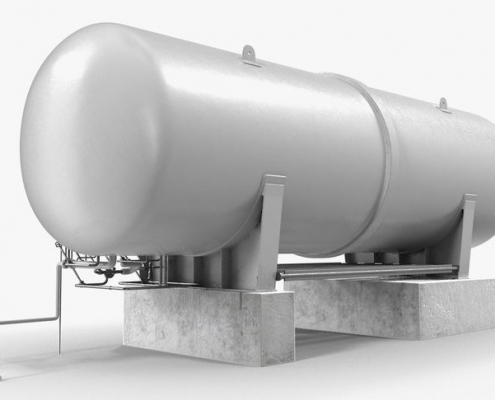

Periodic inspection of Tanks for transporting gaseous liquids:

- Examination of documents (inspections during construction)

- External inspection of the tank (careful inspection of the body, welding lines and possible damage)

- External inspection of the tank (careful inspection of the body, welding lines and possible damage)

- Accurate thickness measurement test with calibration device in sensitive points of the tank

- Perform dredging operations if required

- Hydrostatic test according to test pressure during construction

- Pneumatic test and check the performance of valves and eliminate any leaks

- If there is no discrepancy, the periodic inspection certificate will be issued along with the inspection plate.

Inspection during repair:

- Check the documents of the defective tank

- Refer to the construction standard

- Specialized examination of damaged parts

- Issuance of repair agenda in accordance with construction standards

- Necessary inspections during repairs

- Check repair documents

- Perform non-destructive testing, hardness testing and stress relief as needed

- Hydrostatic test

- If there is no discrepancy, the repair confirmation certificate will be issued.

sure, and is connected to parts of the facility by piping.

sure, and is connected to parts of the facility by piping.